Gas Bottle Storage Requirements – Gas Cylinder Storage Rules – Liquid Propane Storage

The LPG gas bottle storage requirements (gas cylinder storage rules) are set out in the Australian Standards – AS/NZS 1596:2014 – specifying storage and handling of LPG cylinders, both indoors and outdoors.

The gas bottle storage (gas cylinder storage) Standards are rules and requirements that primarily focus on safety and should always be observed.

In a nutshell, the gas cylinder storage (gas bottle storage) Standard states that indoor storage should be avoided whenever possible, and only allows very small sizes, with extensive precaution.

Gas bottle storage requirements include that they should be stored upright in a well-ventilated area and away from any ignition sources.

Summary of AS/NZS 1596:2014 Standard Gas Bottle Storage Regulations – Gas Cylinder Storage

Gas bottle storage regulations (gas cylinder storage rules) are based on the AS/NZS 1596:2014 (Superseding AS/NZS 1596:2008).

They are the primarily LPG gas bottle storage regulations and LPG gas bottle safety-related and should be observed at all times for gas bottle storage (gas cylinder storage) safety and LPG gas cylinder storage safety.

In summary:

- To ensure that any gas leaks from the gas bottles do not accumulate in the gas bottle storage (gas cylinder storage) area, all gas bottle storage (gas cylinder storage) areas must have sufficient ventilation, per gas bottle storage requirements (gas cylinder storage).

- The ventilation must be able to disperse any gas in the gas bottle storage area to safe levels.

- With LPG gas bottle storage regulations¹, the gas bottle must always be upright, disconnected, valves closed, and safety caps on², when not in use.

- Under gas bottle storage regulations (gas cylinder storage), gas bottle storage (gas cylinder storage) must be prevented from falling and protected from impact and damage, especially to the valve.

- Gas bottle storage location regulations require that LPG gas bottle storage (gas cylinder storage) should always be in a well-ventilated area away from any flame, heat, or other ignition source

- Minor indoor LPG gas bottle storage (gas cylinder storage) is permitted under LPG gas cylinder storage rules & regulations¹

- Indoor gas bottle storage safety and gas cylinder storage safety limits on quantity apply. As per AS/NZS 1596:2014 Table 2.1, the maximum quantity of LP gas cylinders indoors or within a roof and 3 or more walls should only be up to 10kg per 10 square metre floor area, up to 30kg.

- Forklift cylinders not being used must be stored outside in well-ventilated LPG gas bottle storage (gas cylinder storage) space. This is typically in a gas bottle storage cage at least 6 metres (20 feet) from other structures.

- LPG should never be stored in excess of 50C (122F) or near a heat source.

- Even though permitted under the gas bottle storage regulations (gas cylinder storage), indoor LPG gas bottle storage (gas cylinder storage) should be avoided whenever possible, for gas bottle safety

¹Gas Bottle Storage Regulations: Australian Standard AS1596-2008 in Section 2;

²Safety cap use where and when applicable

How to Follow the Gas Bottle Storage Requirements

Under the gas bottle storage (gas cylinder storage) requirements (gas bottle storage regulations), it is best advised to store all LPG gas bottle sizes (propane or butane) outdoors.

Since this makes LPG cylinders more vulnerable to natural forces (rain, snow, wind, etc.), it’s best to use cylinders with a corrosion-resistant finish or other surface protection coating.

The outdoor gas bottle storage (gas cylinder storage) space must also be of heavy-duty construction, especially in industrial settings where LPG is required for heating or operation.

If your worksite requires several LPG cylinders stored for reserve, we advise securing them properly with individual safety chains made of heavy-duty steel to prevent unwanted falls and damage to the bottles.

As stated in the previous section, you can store small LPG bottles inside your home.

Under the gas bottle storage (gas cylinder storage) location regulations (gas bottle storage regulations), the limit is 10kg per 10 square metre floor area and a total quantity of 30kg.

That means you can store three 9kg gas bottles if you have a 30-square-metre home.

Note that balconies are counted as indoor spaces.

The standard LPG gas cylinder storage rules (gas bottle storage regulations) specify how much gas bottle storage (gas cylinder storage) you may have inside of a structure, but it varies by structure type and size.

LPG Gas Cylinder Storage Rules

The Standard LPG gas bottle storage (gas cylinder storage) requirements (gas bottle regulations) do specify:

1. Avoid Indoor Gas Bottle Storage Including Not-in-Use Forklift Cylinders

LPG gas bottle storage (gas cylinder storage) and use indoors, whether the gas cylinder storage (gas bottle storage) is full or nominally empty, should be avoided whenever possible, per the gas bottle storage (gas cylinder storage) requirements (gas bottle regulations) and for gas bottle storage safety and LPG gas cylinder storage safety.

LPG gas bottle storage (gas cylinder storage) and use indoors, whether the gas cylinder storage (gas bottle storage) is full or nominally empty, should be avoided whenever possible, per the gas bottle storage (gas cylinder storage) requirements (gas bottle regulations) and for gas bottle storage safety and LPG gas cylinder storage safety.

Forklift bottles not in use should be stored outdoors.

LPG gas bottle storage (gas cylinder storage) should preferably be located outdoors.

2. Knowledge of Storage Hazards and Risks

Having LPG cylinders at home or in your business means you should have basic knowledge of LPG gas bottle storage (gas cylinder storage) hazards and risks associated with improper gas cylinder storage (gas bottle storage) and use.

Make sure the gas bottle is not directly exposed to sunlight when in an outdoor environment.

Contact ELGAS at 1800 819 783 if you see obvious rusting on the surface and its corrosion-free finish has worn out.

Always place gas bottle storage (gas cylinder storage) safety signage on your LPG gas bottle storage space and have chain restraints to secure the cylinders firmly.

3. Upright, Well-Ventilated, and Away from Ignition Sources

LPG gas cylinder storage (gas bottle storage) should always be kept upright and in a well-ventilated area away from any flame, heat, or other ignition source. Forklift gas cylinder storage cages should be at least 6 metres from buildings.

4. Protection from Physical Impact

LPG gas bottle storage (gas cylinder storage) must be protected from any physical impact for gas bottle storage safety and LPG gas cylinder storage safety.

5. Protected from Falling Over

LPG gas cylinder storage (gas bottle storage) should be located so that they are not likely to be damaged or dislodged under normal use circumstances.

LPG gas cylinder storage (gas bottle storage) should be located so that they are not likely to be damaged or dislodged under normal use circumstances.

A retention chain or strap should be used (see image).

Any trolley or stand in which the gas bottle storage (gas cylinder storage) is housed shall be of metal construction and of adequate stability.

6. LPG Gas Bottle Storage Must Not Block Escape Routes or Near Combustible Materials

LPG gas bottle storage (gas cylinder storage) should be kept in a location that does not hinder people’s escape.

LPG gas bottle storage should be well away (at least 6 metres) from any combustible or waste materials.

7. Segregated from Oxidizing and Toxic Gases

LPG gas bottle storage (gas cylinder storage) shall be kept at least 3m from oxidizing gases, like oxygen.

The exception is where the LPG gas bottles and oxidizing gas form part of a portable oxy-fuel system used for welding, brazing, cutting or similar applications.

8. Valves Closed When Not in Use

LPG gas cylinder storage (gas bottle storage) should always be stored with all their valves closed, when not in use, for LPG gas bottle storage (gas cylinder storage) safety.

LPG gas cylinder storage (gas bottle storage) should always be stored with all their valves closed, when not in use, for LPG gas bottle storage (gas cylinder storage) safety.

Any gas bottles in use shall be connected only to an approved appliance and used in accordance with AS 5601/NZS 5261 or other applicable Standards.

LPG gas bottles and their fittings shall be inspected for leaks prior to LPG gas bottle storage (LPG gas storage) or use.

Workplace safety LPG gas bottle storage regulations and guidelines may apply even to quantities defined as minor LPG gas bottle storage (gas cylinder storage) in this LPG gas cylinder storage rules Standard.

New to LPG? Choose ELGAS

ELGAS is Australia’s largest LPG supplier and services the LPG energy needs of more than 350,000 homes and businesses.

Whether you are looking for LPG for your home, LPG for your business, or SWAP’n’GO for your BBQ, contact ELGAS today!

Can You Use a Propane Tank Indoors

According to the Australian Standards, you can store a small propane tank indoors and use a propane tank indoors for things like a wok burner.

According to the Australian Standards, you can store a small propane tank indoors and use a propane tank indoors for things like a wok burner.

The Australian gas bottle storage (gas cylinder storage) location regulations permit you to have 10kg indoors per dwelling.

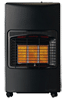

However, you cannot use a propane tank indoors for a cabinet heater, which is a heater with a propane tank inside.

Cabinet heaters are specifically prohibited (see image).

Gas Bottle Storage (Gas Cylinder Storage) Location Regulations at Home

Detached House or Single-Story Attached Dwelling

In Australia, with LPG gas cylinder storage (propane gas bottle storage ) at home, gas bottle storage location regulations permits you to have 10kg indoors per dwelling.

Please note that balconies are considered indoor areas for LPG gas cylinder storage safety.

As there are no 10kg gas bottles available in Australia, the limit for LPG gas bottle storage (gas cylinder storage) at home is effectively one 9kg BBQ-sized gas bottle or two of the smaller 3.7kg BBQ gas bottles.

According to the gas bottle storage location regulations, the maximum gas cylinder storage of combined indoor and outdoor gas bottles (not connected) must not exceed 50kg, and no single gas bottle can exceed 15kg.

Note that 45kg LPG gas bottles connected to your home do NOT fall under this LPG gas cylinder storage limitation.

Multi-Story Attached Dwellings

Once again, in Australia, the gas bottle storage (gas cylinder storage) location regulations permit you to have 10kg indoors, per dwelling, inclusive of balconies.

Shops, Offices & Laboratories (Indoors)

The maximum total quantity is 30kg per occupancy (propane gas bottle storage), with a maximum gas bottle size of 15kg, per the gas cylinder storage rules and for LPG gas cylinder storage safety.

Special Note to Hospitality Establishments

If you have gas patio heaters and you store them inside during non-business hours, you may need to remove the gas bottles before bringing them indoors to avoid exceeding these gas bottle storage regulations (gas bottle storage location regulations) and LPG gas cylinder storage safety limits.

Outdoor areas of hotels, restaurants & cafes

10 kg per 10 m² of floor area, up to a maximum total quantity of 30kg with a maximum gas bottle size of 15kg, per the gas bottle storage (gas cylinder storage) location regulations & propane tank safety regulations.

Factories & Warehouses (indoors)

45 kg per 50 m² floor area, up to a maximum total gas bottle storage (gas cylinder storage) quantity of 180 kg per occupancy with a maximum gas bottle size of 45kg.

Temporary Structures

Special gas bottle storage requirements apply to temporary structures.

This includes open-air and temporary structures such as marquees, tents, booths, and under awnings.

General Gas Bottle Storage Safety & Gas Bottle Storage Requirements

- For LPG gas bottle storage safety, storage should be outdoors in a well-ventilated area. Gas cylinder storage (gas bottle storage) should not be indoors.

- LPG gas is heavier than air and will collect in low areas instead of dissipating. As a result, there must be adequate ventilation and air movement in any gas bottle storage (gas cylinder storage) area.

- If gas is released without adequate ventilation, gas dissipation occurs slowly, and the accumulated gas remains within its explosive range for a longer period.

- Gas cylinder storage (gas bottle storage) areas must be away from ignition sources as per the gas bottle storage regulations (propane tank safety regulations).

- LPG gas cylinder storage must always be stored upright so that the LPG gas cylinder safety pressure relief valve is in the vapour section of the cylinder.

- You should treat any LPG gas bottle that has ever been filled as a full cylinder, even if you believe it to be empty. Only gas cylinder storage (gas bottle storage) purged with inert gas can be once again considered empty.

- Never open the valve of any unconnected gas bottle, even if it is believed to be empty, as there is almost always some remnant gas in every gas cylinder.

- Never have more gas cylinder storage (gas bottle storage) than is required.

- LPG gas bottle storage must prevent falling, movement or physical damage by storing them in approved cages/racks, securing the cylinders with LPG gas cylinder storage safety chains or using other approved retention methods.

- Placarding of gas bottle storage (gas cylinder storage) areas is required by the gas bottle storage requirements when the combined capacity of the LPG gas cylinder storage exceeds 500 litres of water capacity.

An SDS for LPG should be located in close proximity to the LPG gas cylinder storage area for fast reference in a gas bottle storage safety emergency

The Smell of Safety: Gas Leaks & Odourised Gas

LPG (propane and butane) and natural gas (methane) are odourless gases in their natural state.

LPG (propane and butane) and natural gas (methane) are odourless gases in their natural state.

The distinctive smell that people associate with these gases is actually added to them as a safety measure.

When filling, 0.1 to 0.2% of Ethyl Mercaptan (C2H5SH) is added to the gas. It is a sulphur-containing compound that produces an unpleasant odour, like rotten eggs or garlic.

Ethyl Mercaptan is helpful when detecting gas leaks.

If you smell rotten eggs in your kitchen, immediately suspect it is an LPG leak, leave the area immediately, avoid using any electrical appliances, and contact the emergency services (000).

LPG is a highly flammable and combustible gas, so do not try to investigate further, as it could be dangerous.

History of Adding Odourant to Gas

For many decades, the gaseous fuels industry has added odourants to LPG and Natural Gas so that people can detect gas leaks with nothing more than their noses.

Without the addition of an odourant, leaking gas could collect without being detected.

Without the addition of an odourant, leaking gas could collect without being detected.

This would create a dangerous condition that could lead to an explosion or fire.

Much research has gone into the science of odourants and Ethyl Mercaptan is almost universally recognised as the best choice.

As a result, it is the most commonly used odourising agent.

The smell of Ethyl Mercaptan is often compared to rotten cabbage.

The strength of the odourant has caused some people to refer to the process of adding it as “stenching.”

How & When it Gets Added

In the case of LPG, the Ethyl Mercaptan is added to the gas as it leaves the main storage terminals.

The amount added and the process are both carefully controlled.

The terminals themselves have gas detectors that can identify gas leaks without any odourant having been added.

Special Cases with No Odourant

There are certain applications where the odourant is not added.

There are certain applications where the odourant is not added.

Facilities that use odourless gas must have the same gas detection equipment as the gas terminals.

For example, Butane is commonly used as an aerosol propellant.

Needless to say, we wouldn’t want things like hair spray and deodorant to smell like rotten cabbage!

Odourant Fade

Ethyl Mercaptan is not a perfect odourant. Under some circumstances, it can fade away and be replaced by a gentler-smelling odour that might not be recognised as a gas leak.

Odourant fade is rare, but it can happen.

While very few instances of odourant fade have been recorded in Australia, it has happened in other countries.

The presence of rust or moisture within an LPG tank could cause this fade.

To prevent this, new gas bottle storage are filled with dry and inert nitrogen gas, which prevents rust and eliminates moisture.

Once filled with LPG, the risk is virtually eliminated.

What You Can Do

LPG users can also assist in avoiding odourant fade by making sure that all disconnected gas cylinder storage (gas bottle storage) have their valves closed, even when completely empty, to stop air (oxygen) and moisture from getting inside the cylinder.

This helps prevent the possibility of internal rusting.

When gas cylinders are periodically re-inspected, rust and moisture are also looked for.

The presence of either is cause for condemnation of the cylinder.

So, now you know why gas smells the way it does and why it is the ‘Smell of Safety’.

New Residential LPG customer?

New Business LPG customer?

Existing ELGAS customer?

- BBQ – Gas and Charcoal BBQ Features – Charcoal BBQ vs Gas BBQ Comparison - March 31, 2025

- GPL Gas (GPL Fuel) – GLP Gas – LPG Gasul: GLP-GPL Gas Station - March 26, 2025

- Think LPG When Building a New Home - February 26, 2025

Steve Reynolds

Technical Consultant

Steve Reynolds is a leading expert in the LPG industry with over 22 years of experience. As part of the national management team at ELGAS, Steve ensures the safe and efficient storage, handling, and transportation of LPG. He serves as the lead investigator for incidents and collaborates with authorities on industry developments.

Steve is a technical advisor to Standards Australia and Gas Energy Australia (GEA), and an active member of the World LPG Association (WLPGA), contributing to global standards and technical reviews. He holds a BSc. (Hons) in Industrial Chemistry from UNSW and has held senior safety and technical roles at ELGAS, making him a trusted authority in LPG safety and standards.