BBQ Gas Bottles in the Sun – Are BBQ Gas Bottles Safe in the Sun

Can a Gas Bottle Explode in the Sun – Can BBQ Gas Bottles Be Left in the Sun

Why do Gas Bottles Freeze – Gas Bottle Freezing – Ice On Gas Bottle

Many people wonder about BBQ gas bottles in the sun.

They also wonder why do gas bottles freeze.

Gas bottles (propane tanks) in the sun will not explode.

LPG gas bottle is designed to be in the sun or shade, with reflective colours, room for expansion and pressure relief valves.

LPG gas bottle is designed to be in the sun or shade, with reflective colours, room for expansion and pressure relief valves.

Any overpressure gas would vent through the pressure relief valve, not cause an explosion.

For a gas bottle to explode, it would need to be exposed to a rapid increase in heat that can overcome the pressure relief valve.

A significant fire might cause a rupture but a gas bottle will not explode in the sun.

When the gas bottles in the sun temperature rises, so does the gas bottle pressure.

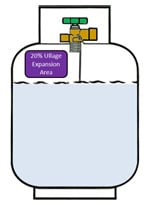

Gas bottles are designed with 20% expansion area for pressure increases and gas expansion.

There is no reason to worry about gas bottles in the sun.

Home gas bottles and service station LPG tanks are both in the sun all day without any problems.

BBQ gas bottles are no different.

All are designed with the same 20% expansion space.

Many people worry about leaving their BBQ gas bottle in the sun.

What about LPG storage temperatures that are artificially high, including being left inside of cars?

LPG gas bottle pressure rises with temperature.

The pressure relief valves will release some of the pressure by venting a small amount of gas, in the unlikely event that the vapour pressure gets too high.

9kg or 20lb BBQ gas bottle in the sun are no more prone to sun heat problems than other gas bottles and tanks.

Avoid LPG gas bottle storage temperatures that are artificially high.

This includes storage inside of cars or near fires, appliances, machinery or any other heat source.

Built-In Room for Expansion – Ullage

LPG BBQ bottles and larger tanks are designed to be full while allowing 20% of the space, called “ullage”, for the natural expansion of the LPG.

LPG BBQ bottles and larger tanks are designed to be full while allowing 20% of the space, called “ullage”, for the natural expansion of the LPG.

In other words, they are oversized.

So, gas bottles in the sun are not a problem.

Reflective Colours

In addition, gas bottles are always white, silver or light grey in colour, to reflect radiant heat.

In combination with the ullage design feature, it makes it exceedingly unlikely that you would ever have a problem in a typical sunny outdoor environment.

Overfilling an LPG Bottle

Overfilling can cause problems, as it would reduce the ullage expansion space.

Overfilling is extremely unlikely with gas bottle exchange programmes, like SWAP’n’GO®, as they fill the gas bottles on digital scales.

Now, the exact OPPOSITE problem…

Why do Gas Bottles Freeze – Gas Bottle Freezing Up – Ice On Gas Bottle

Under the right circumstances, condensation or you can get ice on gas bottle and/or a gas bottle freezing up.

But why do you get a gas bottle freezing?

Condensation Turns to Ice on Gas Bottle – Gas Bottle Freezing Up

Initially, condensation forms when the temperature of the gas bottle or regulator drops below the dew point.

Initially, condensation forms when the temperature of the gas bottle or regulator drops below the dew point.

This is exactly the same as the condensation you get on a humid day with a glass of ice water.

As the temperature continues to drop, the condensation may turn to ice on gas bottle.

But what causes a gas regulator or gas bottle freezing up in the first place?

Can LPG Gas Freeze?

Yes, LPG gas can freeze, but not outside a laboratory.

LPG (propane) freezing point is -188 °C (-306.4°F).

So, you might be able to get it to the freezing point in a laboratory, but not in real life.

Why Do Gas Bottles Freeze – How to Stop Gas Bottles Freezing – Gas Bottle Freezing Up

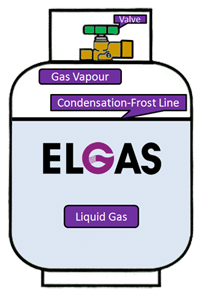

To make sense of why do gas bottles freeze and how to stop gas bottles freezing (gas bottle freezing up), it helps to first explain how LPG works.

LPG is stored under pressure, as a liquid, in a gas bottle.

LPG is stored under pressure, as a liquid, in a gas bottle.

It turns back into a gas by ‘boiling’ into gas vapour.

This happens at the very low temperature of -42°C.To boil, the liquid LPG draws heat from the steel walls of the gas bottle.

This, in turn, makes the gas bottle feel colder than the ambient temperature.

The gas bottle gets even colder when you are actually using the gas.

So, with sufficient humidity and when you are using gas very rapidly, condensation or ice can form resulting in gas bottle freezing up.

This is why gas bottles freeze. As to how to stop gas bottles freezing, there really is no reason to try, as the LPG gas does not freeze and keeps working.

The faster the gas is used, the colder the regulator will get.

The ice on gas bottle will melt as you reduce or stop using you gas appliances.

The visible condensation or frost line indicates the level of the liquid gas remaining in the gas bottle.

Gas Regulator Freezing

A gas regulator freezing can be a problem.

A gas regulator freezing can be a problem.

Before making its way to the LPG appliances in your home, the gas passes through your gas regulator, where the pressure is reduced to the appropriate level.

The regulator delivers a constant safe pressure while the gas bottle pressure can significantly vary, depending on the ambient temperature and the amount of liquid gas remaining in the bottle.

As the LPG passes through the regulator, it expands, resulting in very cold gas vapour temperatures.

This causes the regulator to also reach extremely cold temperatures, as the cold gas vapour passes through it.

Depending on the humidity of the surrounding air and the rate at which the gas is being used, condensation or even gas regulator freezing will occur.

The faster the gas is used, the colder the regulator will get.

This is why, under normal operation in warm and humid climates, the outside of a gas regulator will feel cold to the touch and may also be wet, frozen or frosted.

BBQ Gas Leak Test

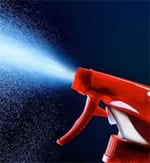

It is important to regularly leak test your BBQ gas bottle, regulator and hose. Leaks from these items are frequently the cause of BBQ gas fires.

How to Test for Gas Leaks

How to Test for Gas Leaks

- Put some soapy water in a spray bottle.

- Turn on the gas bottle without turning on the BBQ.

- Next, spray the entire valve, regulator and hose assembly with the soapy water.

- Bubbles will form if there is a gas leak and you may also smell the gas.

For more details, please see: BBQ Gas Leak Test

Hot To Safely Attach or Change Your BBQ Gas Bottle

Changing gas bottles is not difficult but you do need to know how and you should always test for leaks, when done.

Connecting & Disconnecting Your Gas Bottle

The male connector of a POL regulator has a reverse or left-handed thread.

The male connector of a POL regulator has a reverse or left-handed thread.

LCC27 connectors have right-handed threads.

So, to detach, you turn a POL connector clockwise and then anti-clockwise to re-attach.

Do the exact opposite for an LCC27 connector, detaching anti-clockwise and attaching clockwise.

Remember to do a leak test when done.

New Residential LPG customer?

New Business LPG customer?

Existing ELGAS customer?

- BBQ – Gas and Charcoal BBQ Features – Charcoal BBQ vs Gas BBQ Comparison - March 31, 2025

- GPL Gas (GPL Fuel) – GLP Gas – LPG Gasul: GLP-GPL Gas Station - March 26, 2025

- Think LPG When Building a New Home - February 26, 2025

Steve Reynolds

Technical Consultant

Steve Reynolds is a leading expert in the LPG industry with over 22 years of experience. As part of the national management team at ELGAS, Steve ensures the safe and efficient storage, handling, and transportation of LPG. He serves as the lead investigator for incidents and collaborates with authorities on industry developments.

Steve is a technical advisor to Standards Australia and Gas Energy Australia (GEA), and an active member of the World LPG Association (WLPGA), contributing to global standards and technical reviews. He holds a BSc. (Hons) in Industrial Chemistry from UNSW and has held senior safety and technical roles at ELGAS, making him a trusted authority in LPG safety and standards.