BBQ Gas Leak: Leaky Gas – How Do You Check for a Gas Leak – How Do You Test for a Gas Leak

BBQ Gas Leaks – How Do You Check for a Gas Leak (Leaky Gas)

If you have leaky gas (a gas leak), you need to know how do you test for a gas leak (how to check for gas leak) in home.

The soapy water gas leak test will help you check for a gas leak in home on a BBQ (how to find a gas leak).

The bubbles are how you test for a gas leak in home (how to check for gas leak) or BBQ (leaky gas).

It’s simple gas leak detection to find a gas leak in home when you a gas leak smell (leaky gas).

The soapy water test for a gas leak (leaky gas) allows for tell-tale gas leak detection soap bubbles that are indicative of a gas leaks.

To perform the gas leak test, you just coat all of the gas transmission gear (pipes, hoses & valves) with soapy water and then pressurise the system, without turning on the gas BBQ.

If you see gas leak detection soap bubbles or smell rotten eggs, you know you have leaky gas (a gas leak).

It is important to know how do you check for a gas leak (how to find a gas leak) and test every time you change BBQ gas bottles and regularly do a gas leak test on the gas BBQ, BBQ gas bottle, gas regulator and hose using the soap bubble test for leaky gas (a gas leak).

BBQ gas leaks from these items are frequently the cause of gas BBQ fires.

Leaky Gas or Gas Leaks

Leaky gas or gas leaks are defined as the unwanted escape of gas.

Leaky gas (a gas leak) can originate from a gas appliance, gas bottle, gas pipe or gas fitting.

A natural gas or LPG gas leaks (leaky gas) is dangerous because of the risk of a gas fire or gas leak explosion.

Sometimes with leaky gas (a gas leak in home), gas leak detection is hard, to find gas leaks (how to check for gas leak).

Knowing where to look and the gas leak detection methodology to check for gas leaks (leaky gas) is important.

What to Do if You Think You Have a Gas Leak:

- Turn off gas at the gas bottles or gas meter as soon as possible.

- Do NOT use light switches, telephones, electrical appliances, or anything that could generate a spark or have an open flame.

- Open all doors and windows, if safe to do so, to allow gas to disperse.

- Close basement door, if applicable, to minimise gas settling in the basement.

- Evacuate, leaving the home (building) and the surrounding area.

- Call for professional help from a safe location. Contact your gas supplier, gas fitter, or local 000 emergency services.

Why a Gas Leak is a Serious Problem

- Gas leaks are dangerous.

- A gas leak can result in a gas fire or even a gas leak explosion, if the gas concentration is between 2.15% and 9.6% of the total LPG/air mixture (the limits of flammability for propane), and an ignition source is present.

- Inhaling gas poses a health hazard, with nausea, headache, dizziness, vomiting among other symptoms.

- Direct contact with liquid LPG can result in serious frostbite.

- Natural gas is a powerful greenhouse gas, much worse than CO2, if released into the atmosphere. LPG is NOT a greenhouse gas, so does not pose the same hazard.

- In very high concentrations, asphyxia can result, as the gas displaces the oxygen, leading to a loss of consciousness and even death.

Signs of a Gas Leak

Here is a summary of eleven gas leak detection signs of a gas leak (leaky gas) in your home:

- Your nose is you best gas leak detector sensor, when you detect the gas leak smell of rotten eggs

- Your ears are another gas leak detector sensor, when you hear a gas leak (leaky gas) hissing noise as gas leak detection

- An electronic gas leak detector sensor alarm

- Increased gas bills more than usual can be the sign of gas leaks (leaky gas)

- Seeing moving dust or a white mist is a visual gas leak detection sign of leaky gas (a gas leak in home)

- Yellow, orange, or red gas flame colour can be gas leak symptoms

- Scorching or soot in an unusual location on the gas appliance is another visual method of gas leak detection

- Gas pilot light keeps going out can be caused by leaky gas (a gas leak in home)

- Dead or dying plants in the kitchen or near the gas appliance are gas leak (leaky gas) symptoms

- Some insects are attracted to leaky gas (a gas leak in home). Think of them as a live gas leak detector sensor

- Feeling unwell are physical gas leak (leaky gas) symptoms

Leaky Gas – How to Find a Gas Leak in Home – Gas Leak Detection

To find a gas leak in home (how to check for gas leak), using your nose for gas leak detection is the first step to find leaky gas (a gas leak smell).

The first hint would be the gas leak smell of rotten cabbage or rotten eggs.

An odourant – Ethyl Mercaptan – is added to the naturally odourless LPG and natural gas for the aid in detection of leaky gas (a gas leak smell).

Summary of Soap Test for Gas Leaks in Home

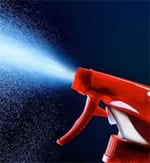

To test for a gas leak in home (how to check for gas leak), apply soapy water to the entire hose assembly, including the gas bottle valve and regulator, using a spray bottle or sponge.

Pressurise the gas system without turning on the gas BBQ.

If you see gas leak detection bubbles or detect the gas leak smell of rotten eggs, you have found your leaky gas (a gas leak).

Soap Test for Leaky Gas – Gas Leaks Check Solution

To make the gas leaks solution for the soapy water test for leaky gas (a gas leak), simply mix dish detergent with water.

The soap can be put in a spray bottle or placed in a bowl for sponging on.

The soap can be put in a spray bottle or placed in a bowl for sponging on.

Dish washing soap is formulated to make lots of bubbles so it works better for the soapy water test for leaky gas (a gas leak).

Liquid laundry detergent doesn’t work as well as dish soap, as it is formulated to be low sudsing, making it harder to see the gas leaks (leaky gas) gas leak detection bubbles how to check for gas leak (leaky gas).

Remember to cover the entire hose assembly from the gas bottle valve to the hose attachment to the gas BBQ or gas heater with soap solution to test for a gas leak (how to check for gas leak).

Open the valve to pressurise the system, without turning on the gas BBQ burners, and look for gas leak detection soap bubbles or sniff for the gas leak smell of rotten eggs.

This quick 60 second video shows how to test for a gas leak (how to check for gas leak) by performing the soap bubble test for leaky gas (a gas leak) – soapy water test for gas leaks (leaky gas):

How to Do Soapy Water Gas Leaks Test – How to Find Leaky Gas (how to check for gas leak in home)

♦ To test for a gas leak in home (how to check for gas leaks), start by putting some soapy water in a spray bottle or a dish.

♦ Turn on the LPG gas bottle without turning on the gas BBQ. This pressurises the system to make any gas leaks (leaky gas) show.

♦ Next, spray the gas BBQ, valve, regulator and hose assembly with the soapy water.

♦ Alternatively, you can apply the soapy water with a paint brush, basting brush or it can even be sponged on.

♦ Gas leak detection bubbles will form if there is leaky gas and you may also detect the gas leak smell.

♦ You need to test the entire assembly from the gas bottle valve all the way to where the gas hose attaches to the gas BBQ.

♦ When done, rinse with clean water to remove the soap solution.

♦ Remember to always soapy water test for gas leak (leaky gas) the lot every time you re-connect your gas bottle.

If you find leaky gas (a gas leak in home), turn off the gas bottle immediately!

Do not turn back on or attempt to use the gas BBQ until the gas leak (leaky gas) is rectified.

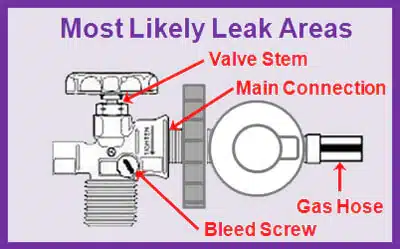

How Do You Check for a Gas Leak in Home – Common Problem Areas

How Do You Check for a Gas Leak on a BBQ Gas Bottle

Gas leak detection to check for a gas leak on a BBQ gas bottle (how to find a gas leak), perform the soapy test for gas leaks (leaky gas) around the valve and connections.

You use the same test to check for a gas leak in home and to check for gas leaks (leaky gas) on a gas bottle as the method of gas leak detection.

Poor connection to the gas bottle is the most frequent cause for leaky gas (a gas leak).

In many cases, the gas leak is caused when the main connection is just not sufficiently tightened.

Dirt or damage to the connectors are also common causes of leaky gas (a gas leak).

Main Connection Can be the Cause of a Gas Leak

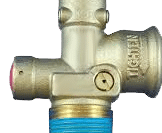

The standard BBQ gas regulator in Australia is a LCC27 or POL gas regulator.

An insufficiently tightened connection is a common cause for a gas leak (leaky gas).

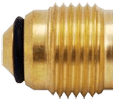

The male connector of the gas regulator, which screws into or onto the gas valve on your BBQ gas bottle, may have a rubber O-ring seal or it may rely on a metal to metal contact seal.

The male connector of the gas regulator, which screws into or onto the gas valve on your BBQ gas bottle, may have a rubber O-ring seal or it may rely on a metal to metal contact seal.

You should always inspect the regulator for damage, paying special attention to the connector, which screws into the BBQ gas bottle and check for a gas leak (how to find a gas leak).

If it has a rubber O-ring, it also needs to be undamaged.

The connector and the female valve opening should both be clean and undamaged.

Pieces of dirt, nicks and scratches can prevent the two components from sealing, resulting in leaky gas (a gas leak).

Gas Hose

The gas hose is attached to the regulator on one end and the gas BBQ on the other end.

The gas hose is attached to the regulator on one end and the gas BBQ on the other end.

It can become damaged or deteriorate with age, causing leaky gas (a gas leak).

Dogs and other animals can also cause damage by chewing on the dangling hose.

Visually inspect the gas hose for cracking, splitting or other damage to find gas leaks (leaky gas).

You should replace the gas hose if it shows any signs of damage or degradation to prevent gas leaks (leaky gas).

It is good practice to replace the entire BBQ regulator and hose assembly, if it is old enough for the hose to have deteriorated, as regulators also wear with age, ending up with a gas leak (leaky gas).

Gas Leak Around the Valve Stem

In Australia, BBQ gas bottles must be tested every ten years.

In Australia, BBQ gas bottles must be tested every ten years.

The gas valve is changed upon inspection and the valves are expected to last for the full ten years.

However, occasionally the valve will fail prematurely and could develop a gas leak (leaky gas) from around the valve stem.

This is rare but it can happen.

Please see Gas Bottle-Cylinder Testing Facts for more information on the ten year testing process.

Gas Leaks from the Bleed Screw

The bleed screw is a small slotted screw on the side of the BBQ gas bottle valve that lets gas vapour bleed off during the decanting refill process.

The bleed screw is a small slotted screw on the side of the BBQ gas bottle valve that lets gas vapour bleed off during the decanting refill process.

The refill technician opens it during the filling process and closes it, when done.

The screw can develop a slow gas leak (leaky gas) if it becomes loose, so you check for a gas leak (how to find a gas leak).

When to Test for a Gas Leak in Home

Check for gas leak (leaky gas) on the BBQ gas bottle, regulator & hose assembly using the soapy water test for a gas leak (how to find a gas leak in home) every time you reconnect your regulator to the BBQ gas bottle to the gas BBQ.

You should also do gas leak detection by using the soapy water gas leak (leaky gas) test (how to check for gas leak) after any long period of non-use, such as at the beginning of gas BBQ season.

Soapy Water Solution For Soapy Water Gas Leak Test

You will need a soapy water solution to do the soapy water test for a gas leak (how to find a gas leak).

You will need a soapy water solution to do the soapy water test for a gas leak (how to find a gas leak).

Mixing liquid hand soap with water should work fine.

Place the solution in a liquid spray bottle.

It’s a good idea to leave the spray bottle with the BBQ, so it’s always a handy reminder to perform the soapy water test for a gas leak (leaky gas).

No Ammonia

Your BBQ valve and fittings are made from brass.

You must never use any soapy water gas leaks test solution that contains ammonia, when you do your testing for leaky gas (how to find a gas leak).

Ammonia can cause brass to become brittle and crack.

Be aware that ammonia is found in many pre-prepared glass and surface cleaners, so make sure you read the label before use.

Extra Safety Tip

The best practice gas safety advice is that BBQ gas bottles should only be in a vehicle for the minimum required transport time.

The best practice gas safety advice is that BBQ gas bottles should only be in a vehicle for the minimum required transport time.

When you do transport a BBQ gas bottle, you should consider one added precaution.

After making sure that the valve is firmly closed, you should do a soapy water test for a gas leak (how to find a gas leak) on the entire valve assembly to check for any possible gas leaks (leaky gas), prior to transport.

DO NOT leave BBQ gas bottles in enclose vehicle unnecessarily.

New Residential LPG customer?

New Business LPG customer?

Existing ELGAS customer?

- BBQ – Gas and Charcoal BBQ Features – Charcoal BBQ vs Gas BBQ Comparison - March 31, 2025

- GPL Gas (GPL Fuel) – GLP Gas – LPG Gasul: GLP – GPL Station Near Me - March 26, 2025

- Think LPG When Building a New Home - February 26, 2025

Steve Reynolds

Technical Consultant

Steve Reynolds is a leading expert in the LPG industry with over 22 years of experience. As part of the national management team at ELGAS, Steve ensures the safe and efficient storage, handling, and transportation of LPG. He serves as the lead investigator for incidents and collaborates with authorities on industry developments.

Steve is a technical advisor to Standards Australia and Gas Energy Australia (GEA), and an active member of the World LPG Association (WLPGA), contributing to global standards and technical reviews. He holds a BSc. (Hons) in Industrial Chemistry from UNSW and has held senior safety and technical roles at ELGAS, making him a trusted authority in LPG safety and standards.